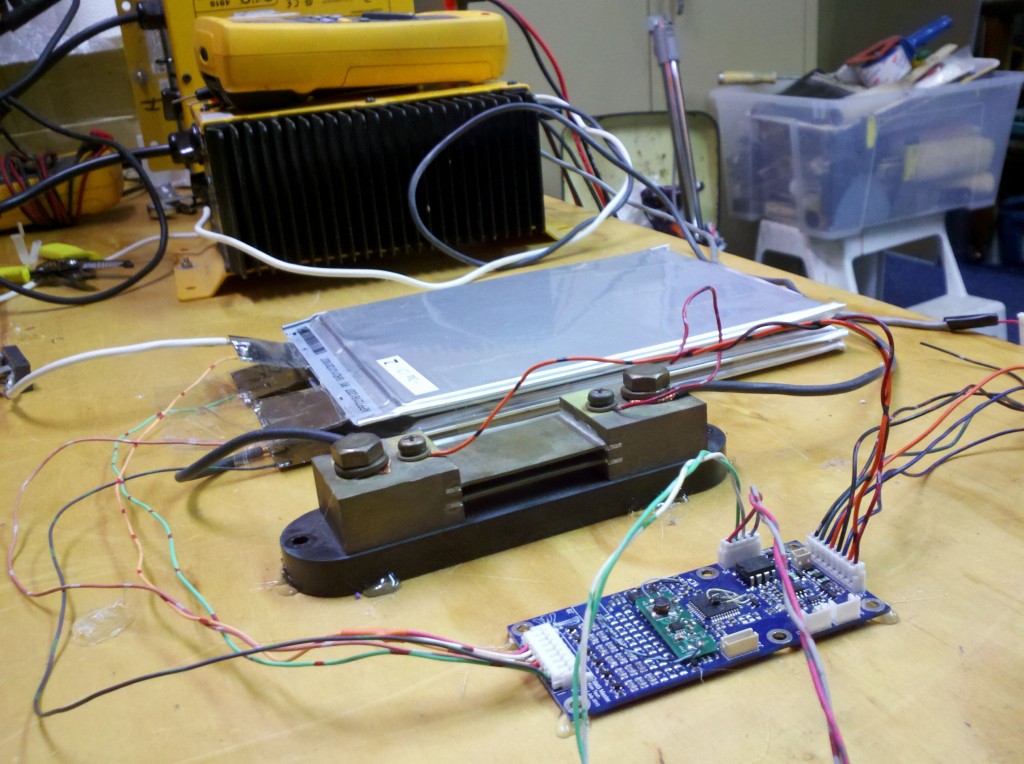

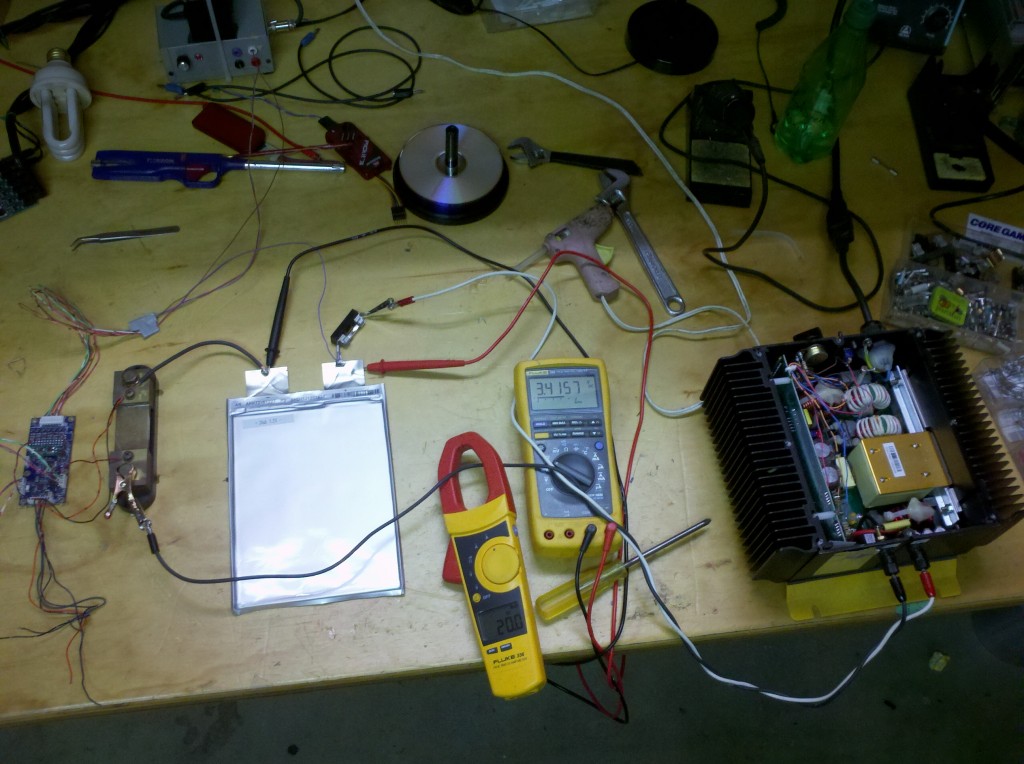

The 3 cells are now assembled into a pack, which will speed up testing compared to doing each individually.

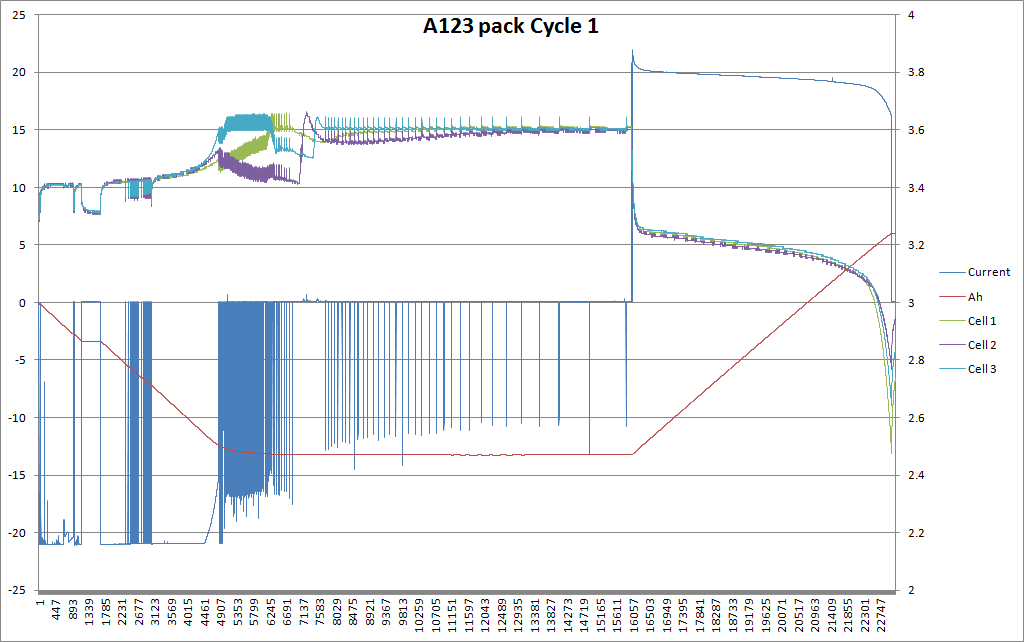

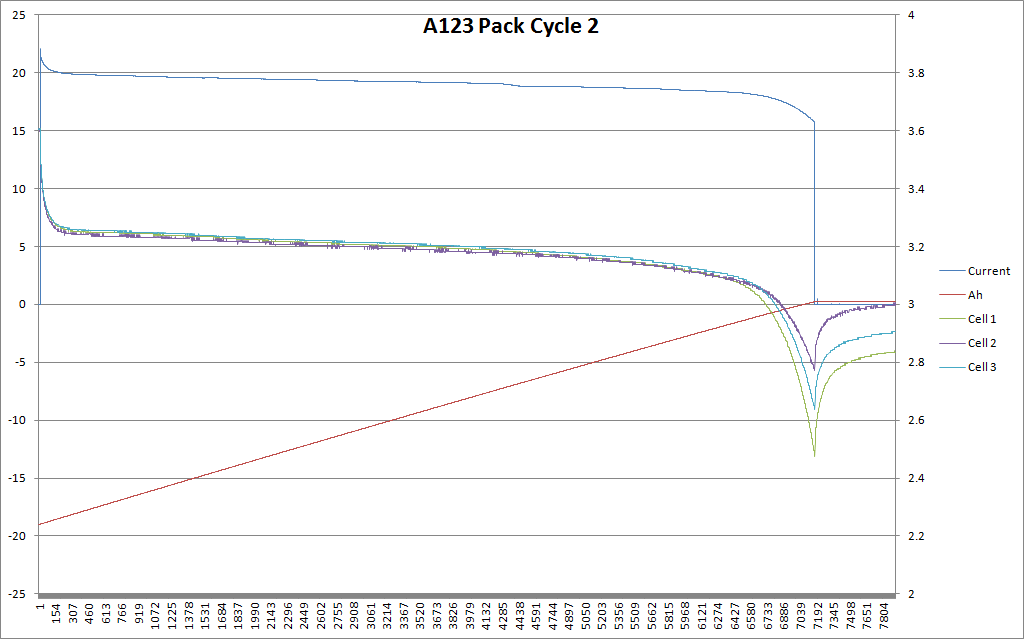

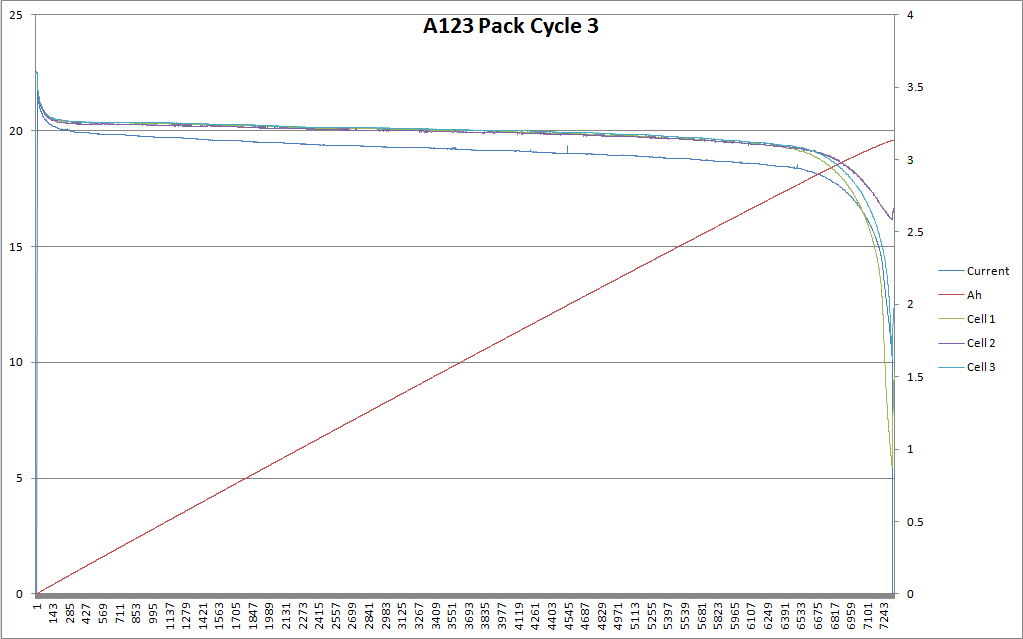

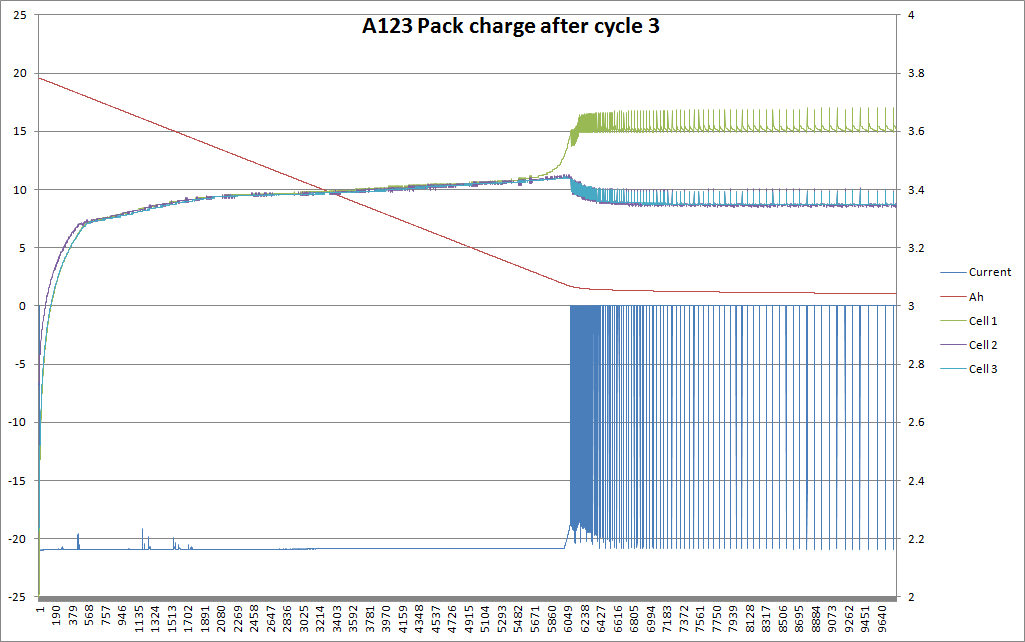

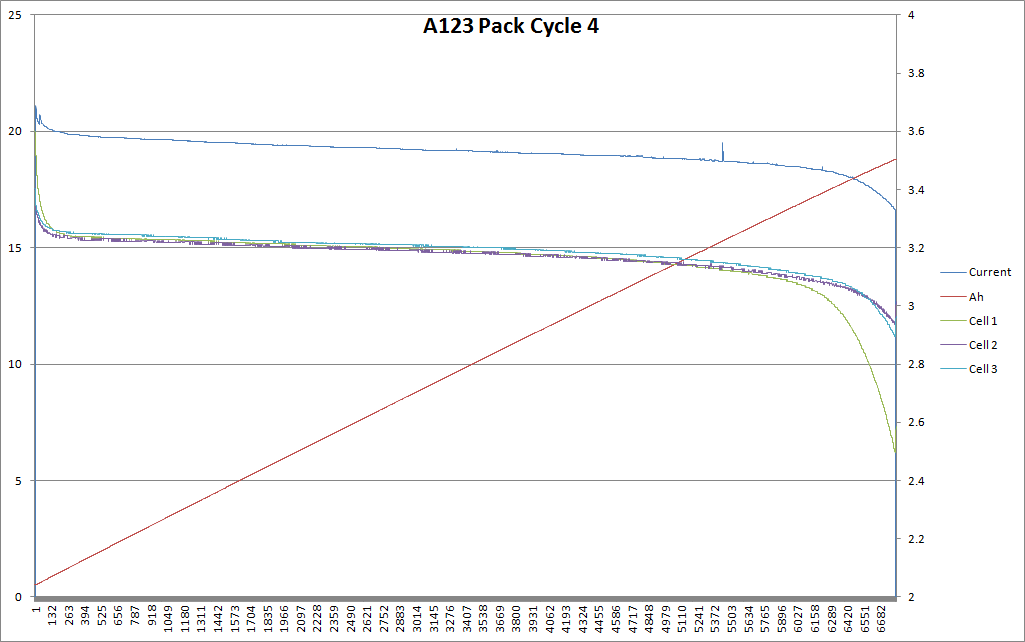

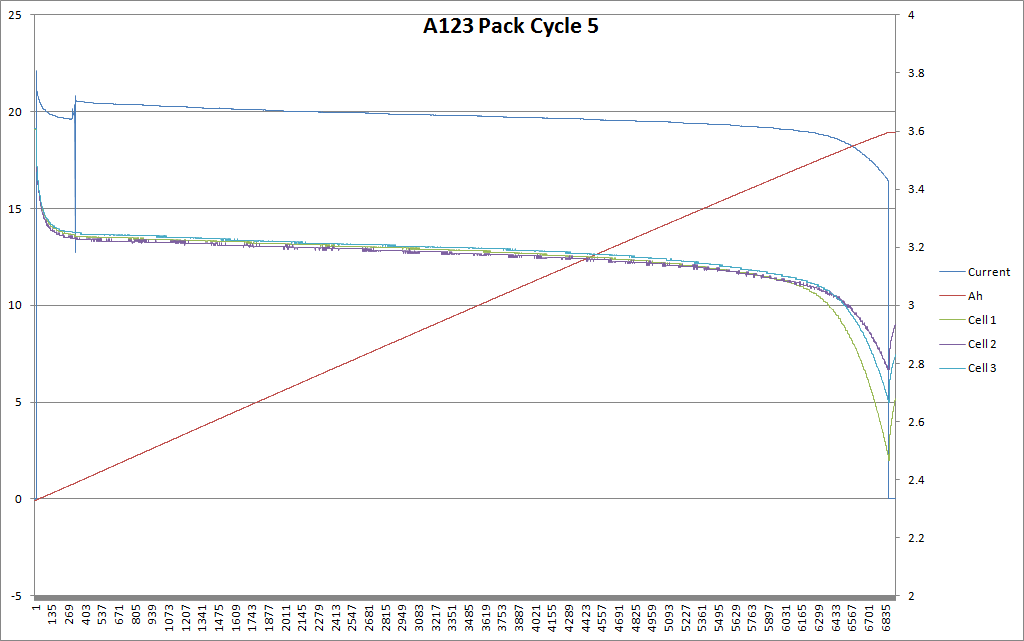

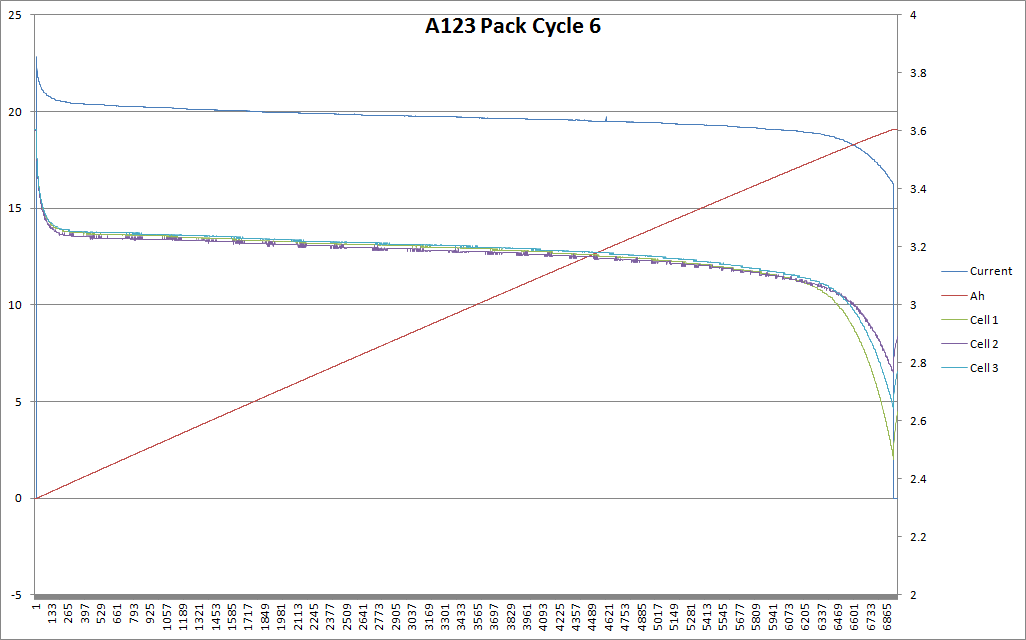

6 cycles have been performed on the pack so far, and the performance has been consistently around 19Ah. On cycle 3 the pack was accidentally over discharged, causing a temporary reduction in capacity that appears to be recovering over several cycles.

Cycle Capacity Notes 1 19.25Ah 2 19.22Ah 3 19.20Ah 1 4 18.28Ah 5 19.00Ah 6 19.10Ah

Notes

1. Accidentally overdischarged to <1Vpc on cell 1. Ah value includes discharge only to 2.5Vpc

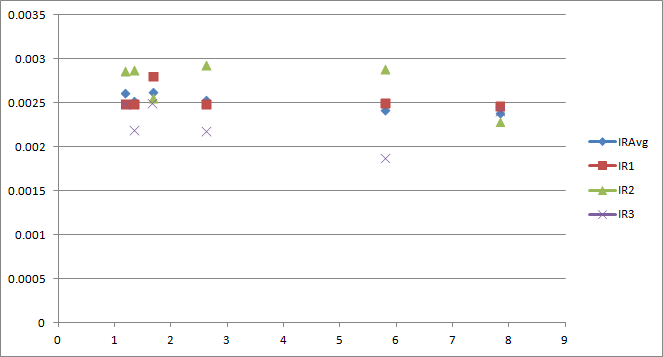

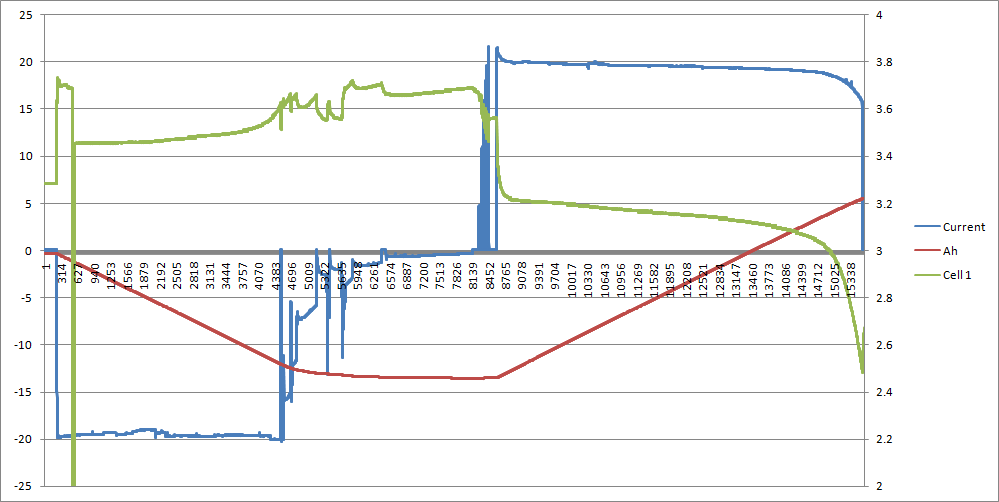

The cell internal resistance averages 2.5mOhm with some spread over time and cell that’s measured. The load was varied from 20A to 36A and voltage deltas used to calculate the internal resistance. X axis on the graph below is Ah discharged from full charge.

Raw data: A123 Battery Data