Fix your flickering lamps without a new switch!

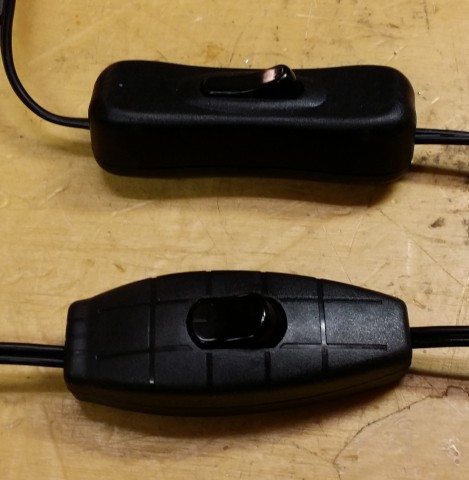

The Ikea Jansjö is my favorite desk work lamp. Some of the older ones have problems where they start flickering or stop working entirely. This is often due to bad IDC contacts in the switch. Several tutorials suggest replacing the switch as a fix, claiming the switch is not openable. Not true, you can open the switch with the right tools.

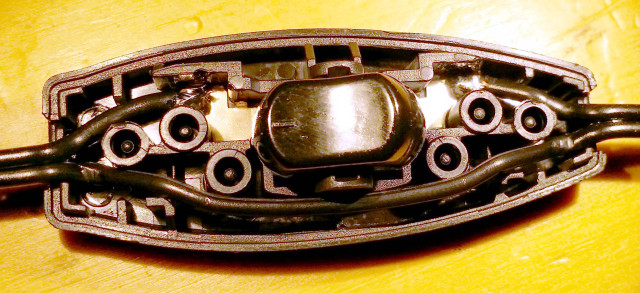

The problem appears to be mainly on the old switch design with curved sides (bottom), not the newer design (top):

Instrutions

1. Open the switch

Use a pair of external snap ring pliers to open the switch. Insert them into the wire entry port and squeeze, being careful not to pinch the wire. Open one side by about 1cm, then switch to the other size to fully open the swtich. Beware of the two clear plastic strain relief pieces that may pop out from each wire entry port.

2. Prepare the wires

Carefully pull the wires out of the IDC contacts. Use a small screwdriver to hold the metal contacts down if needed to avoid pulling them out of the plastic. Strip the wires starting at the position where the contacts bit through the insulation.

3. Solder the wires in place

Use a small tip soldering iron. Place the stripped wire back in the IDC contact. You may need to push the contact open to allow it to fit.

4. (Optional) apply contact protectant

Poly phenyl ether (PPE) is a super slow evaporating oil often used to protect contacts. It’s claimed to stay on for up to 40 years. This is easiest applied with a PPE-containing contact cleaner. One such product is MG Chemicals Super Contact Cleaner with PPE. Applying this may extend the life of the switch.

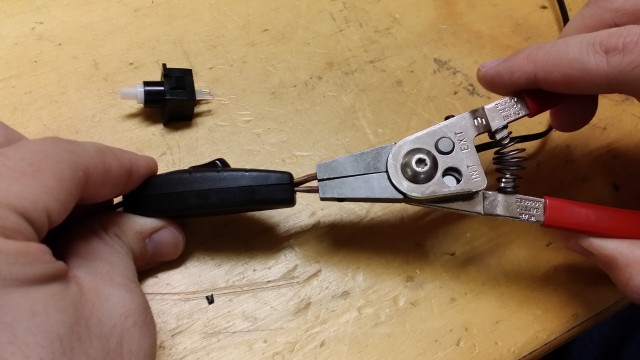

5. Cut off broken locking pins

The case is held together with friction fit pins, some of which may break off while opening the switch. Cut off any protruding nubs that are stuck on the ends of the top portion of the switch. A broken off nub is shown between the jaws of the cutter.

6. Close the switch

Place the wires back into the switch, then put the clear plastic strain reliefs back in. Place the switch on a solid table, place one palm of each hand on each side of the switch, and press down. You’ll have to push down very hard, don’t worry about the switch breaking. You may need to put all your weight into it. You may need to use pliers if you can’t push it down hard enough. Protect the switch with a cloth for example if using pliers.

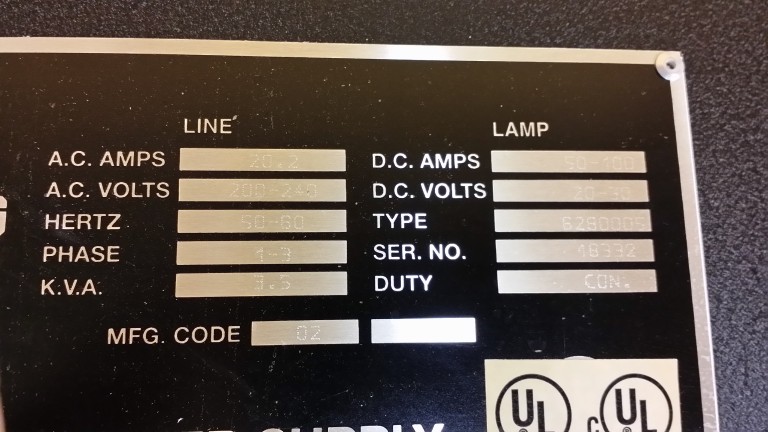

7. Do what UL should have done

This POS switch doesn’t deserve UL approval, so remedy that with a Sharpie.