This is a Strong model 62-80005 Xenon short arc lamp ballast, out of the now demolished Station Square cinemas at Metrotown. This drove lamps up to 2.5kW for the small auditoriums in the cinema. The large auditoriums ran up to 6kW lamps.

Here’s the User manual

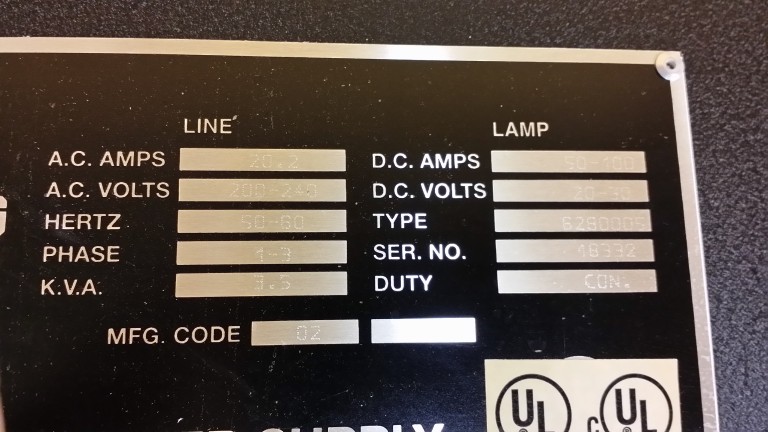

Ratings are

200-240V 1-3 phase 20.2A input

20-30VDC 50-100A output

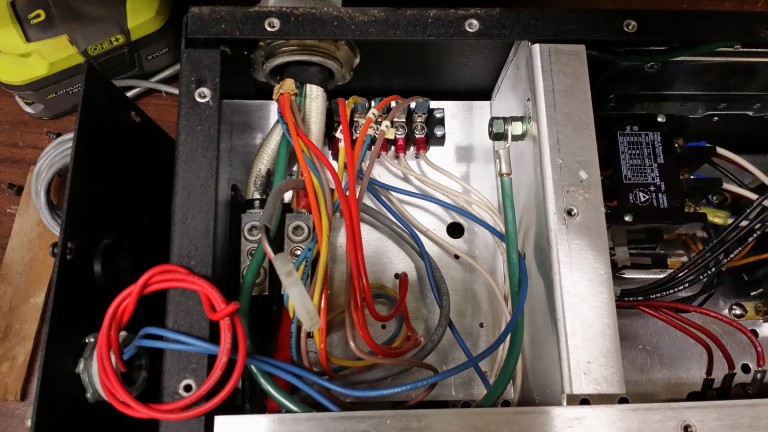

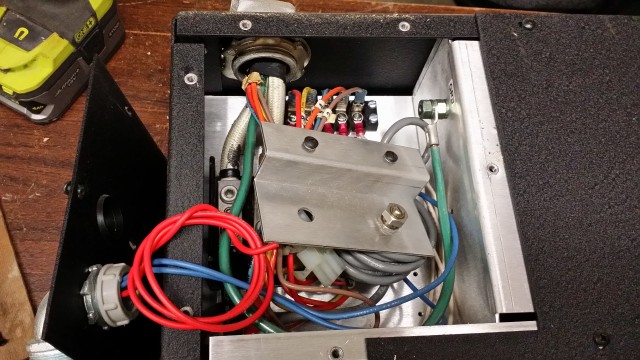

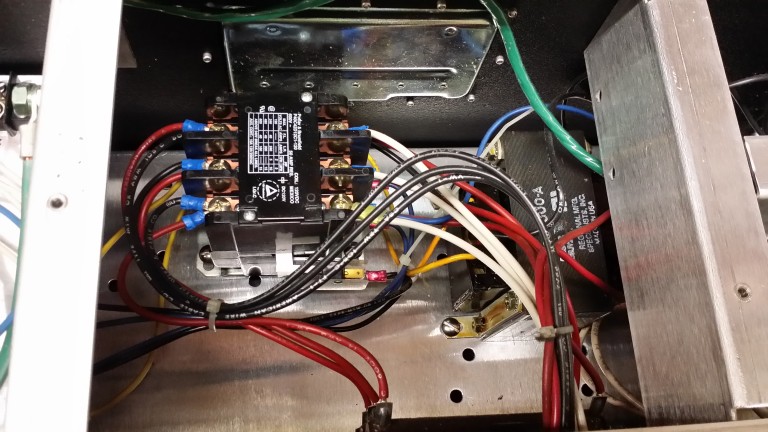

We were greeted with the lamp current control pot jammed in the output junction box by the installers.

We were greeted with the lamp current control pot jammed in the output junction box by the installers.

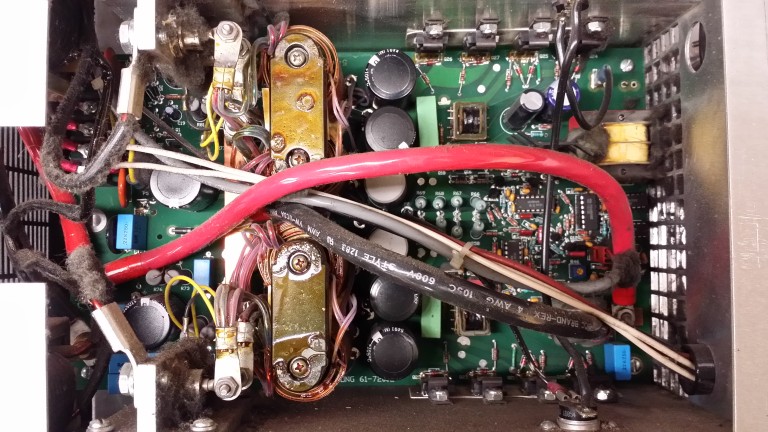

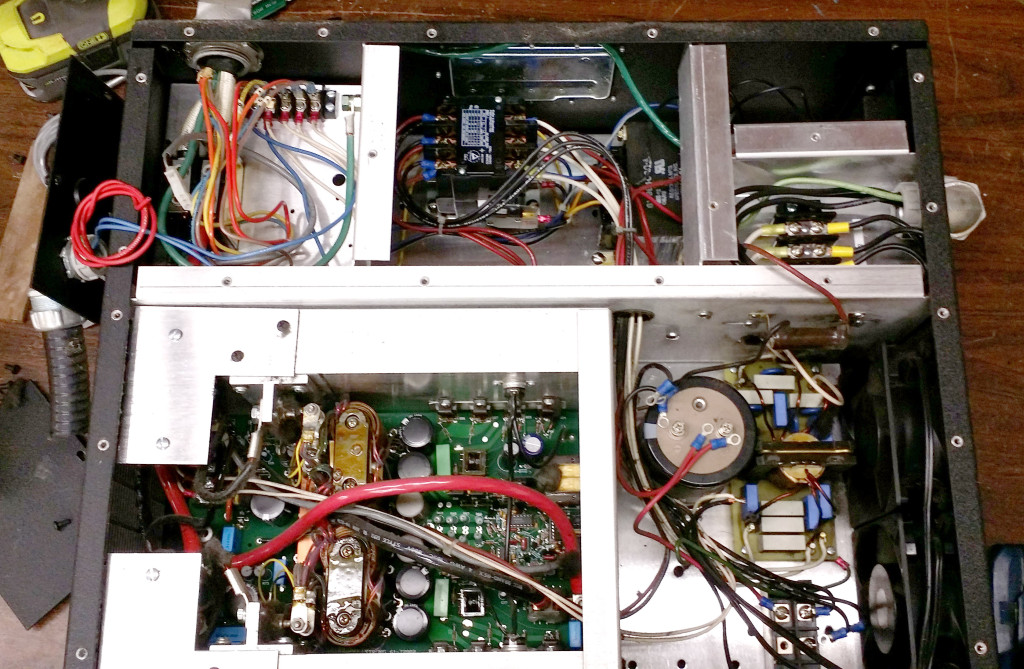

This ballast dates from 1998, and appears to be an older design. As expected, it’s built very well, with the entire chassis being aluminum.

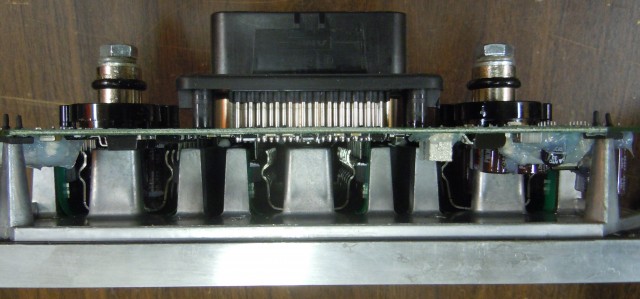

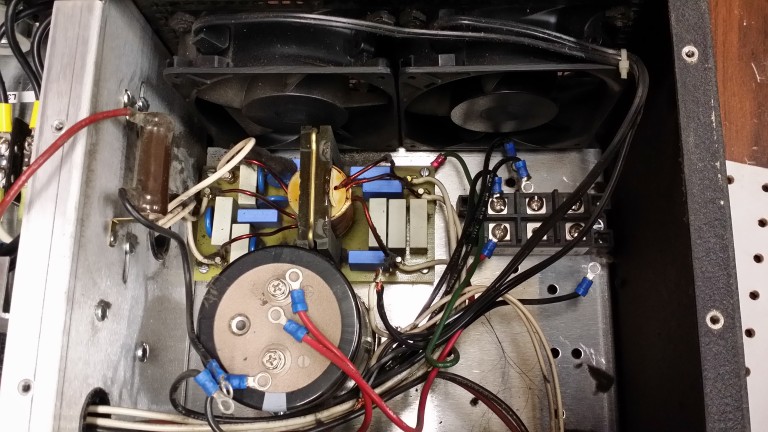

In the above photo, 3-phase input connections are on the top right, bus capacitor precharge contactor top middle, DC output top left. On the bottom right is the EMI filter and main bus capacitor (6800uF 350V), and the bottom left contains the actual switching power supply unit.

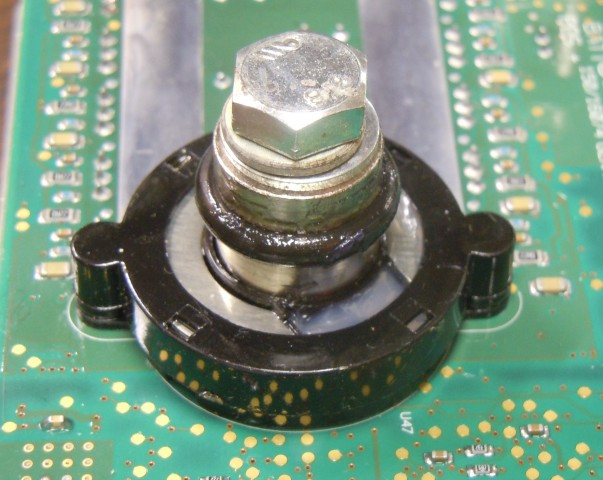

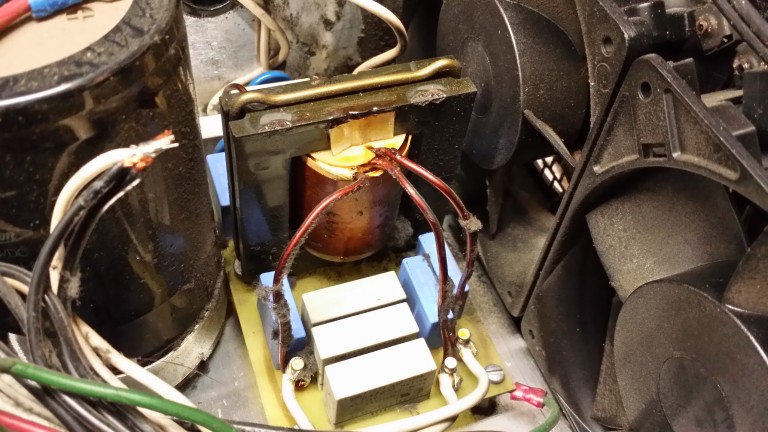

Close up of the contactor and 240-120V transformer used to run auxiliary systems in the projector. Also contains the three 5ohm 50W bus precharge resistors, which the contactor shorts out once the bus cap is charged. This avoids blowing the input breaker when turning on the power and charging up the capacitor.

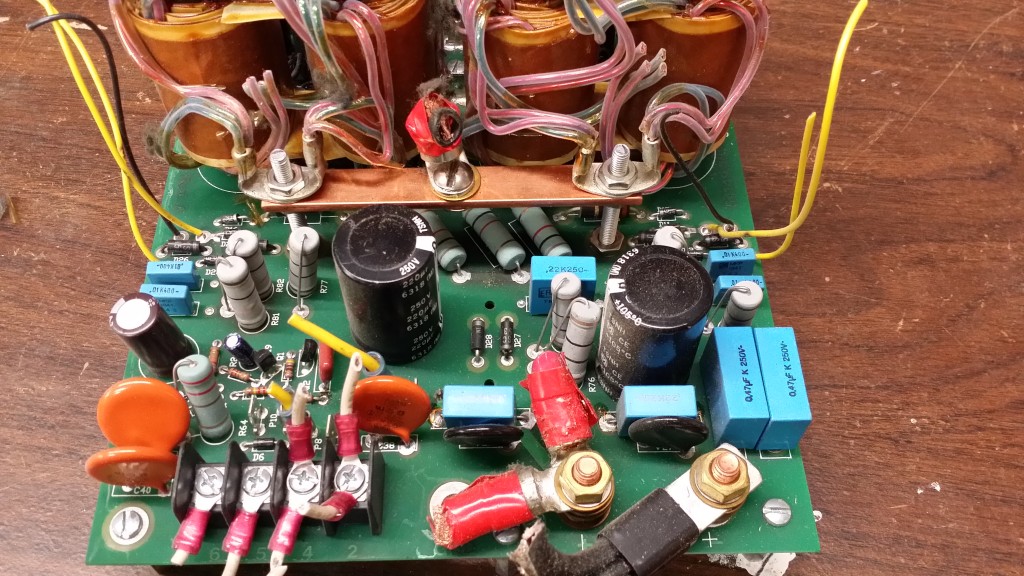

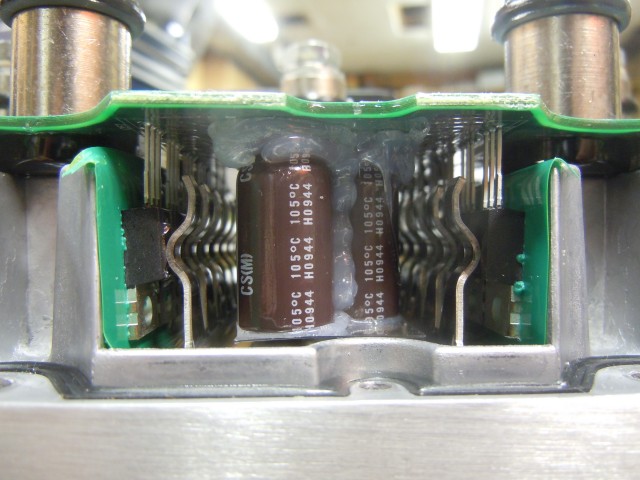

EMI filter, DC bus cap and input rectifier. Bus cap bleeder resistor also visible on the left.

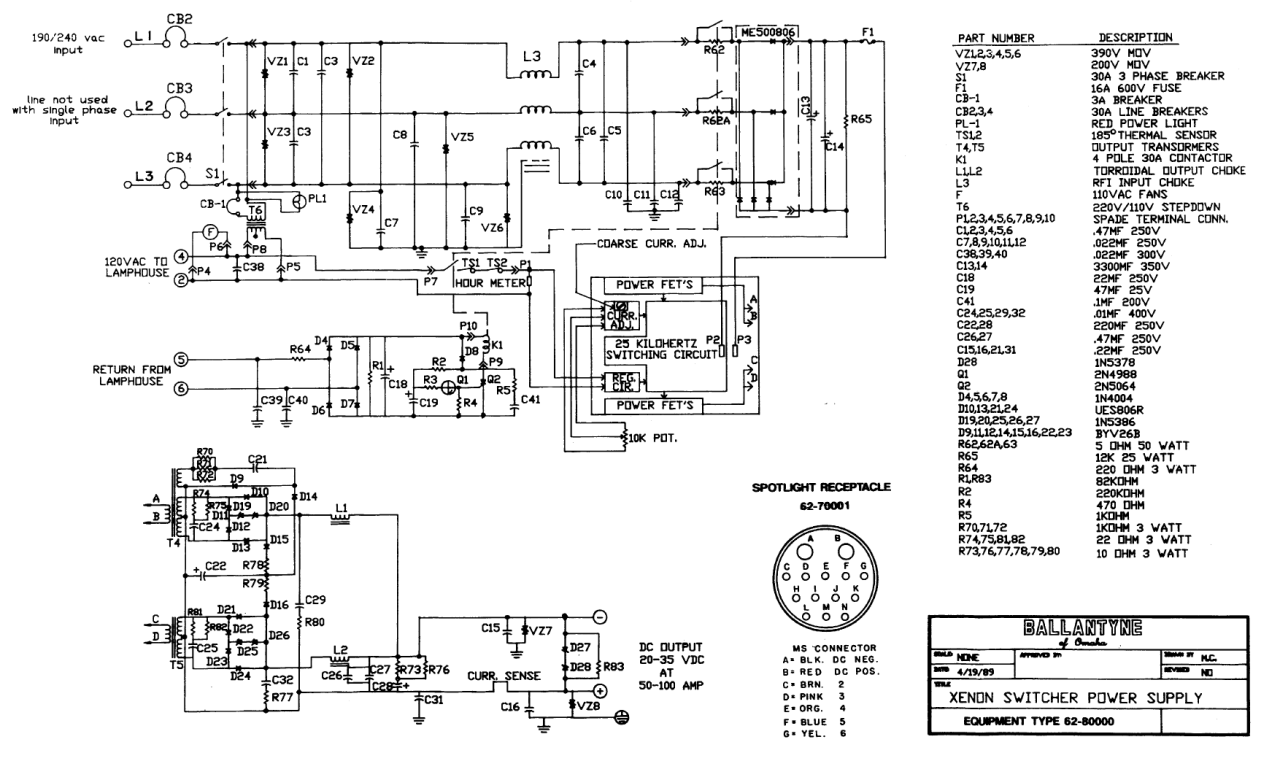

Schematic from manual. It’s basically two separate paralleled full bridge converters with full wave centertapped output rectification.

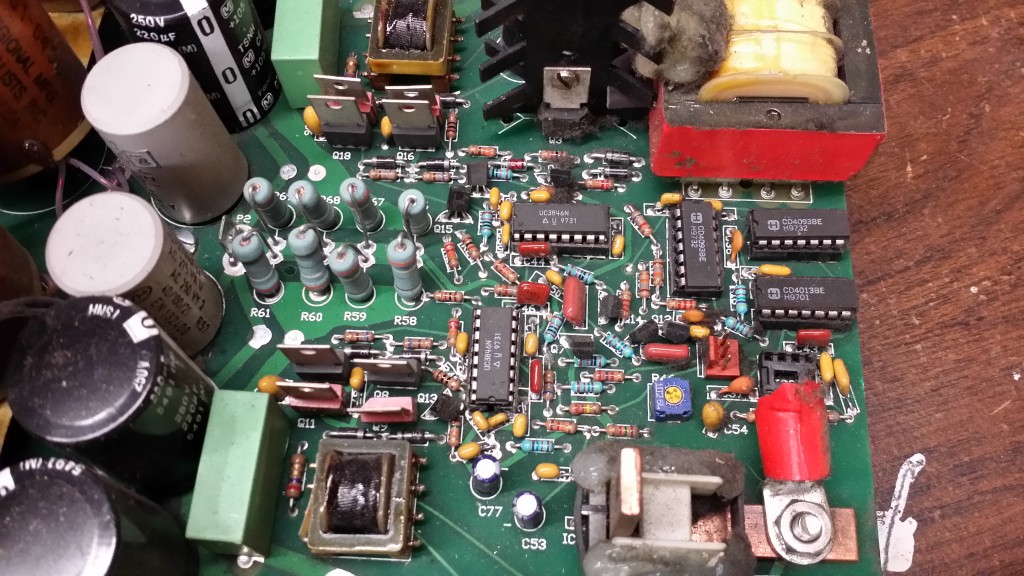

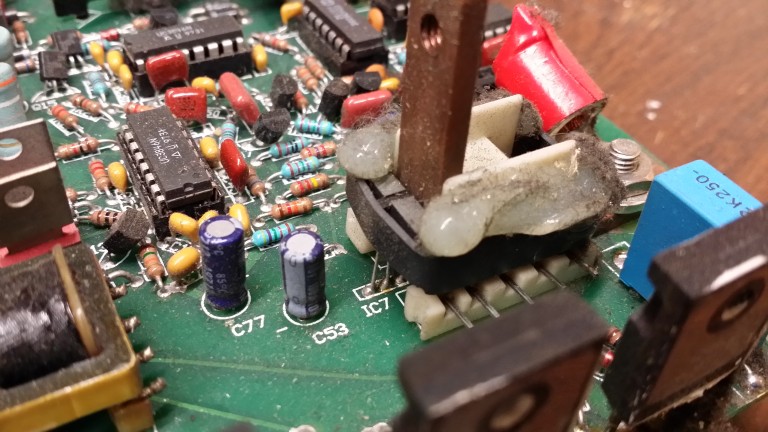

Control section has a very “organic” layout, the designer must have really been cramming to get everything to fit.

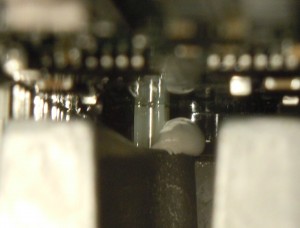

The output current sensor is clever, just a standard ferrite core with a hall sensor stuck in the core gap. Probably much cheaper than the commercial versions of these sensors, especially at this current rating.

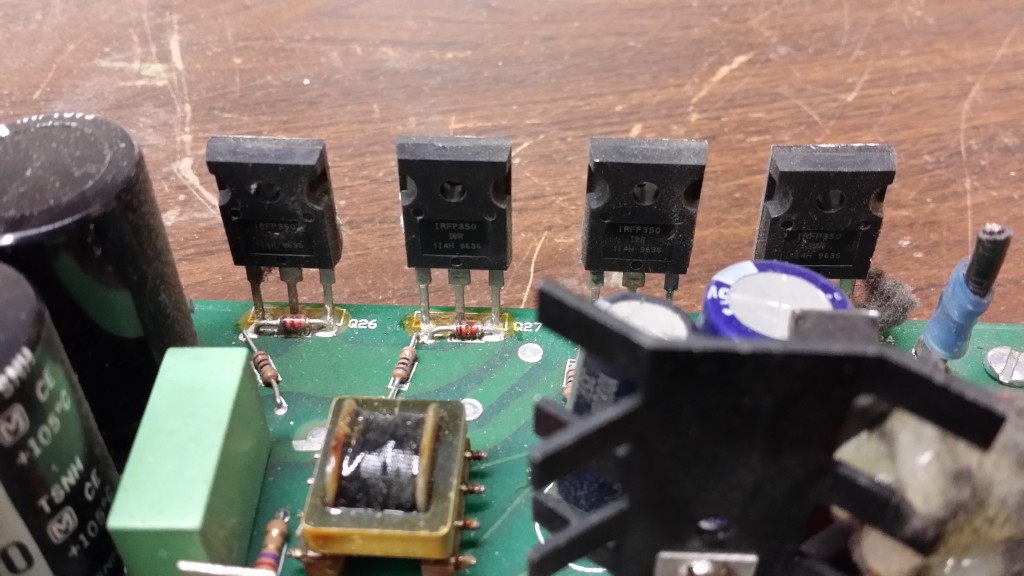

IGBTs are IRFP350 rated 400V 16A

IGBTs are IRFP350 rated 400V 16A

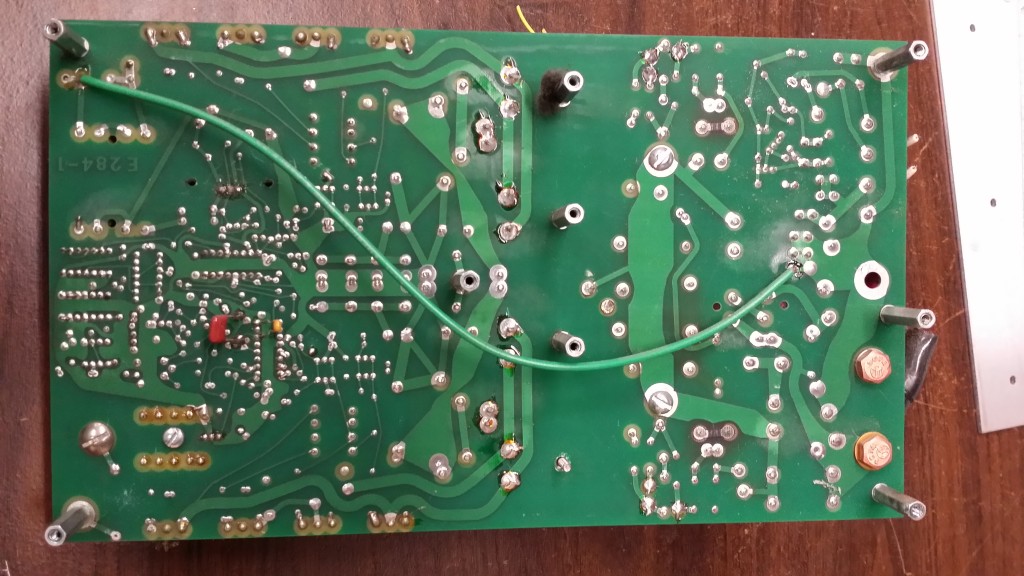

Not too bad – only a few bodge wires/components. I figure the green wire was for some safety ground purpose and and not EMI.

Not too bad – only a few bodge wires/components. I figure the green wire was for some safety ground purpose and and not EMI.

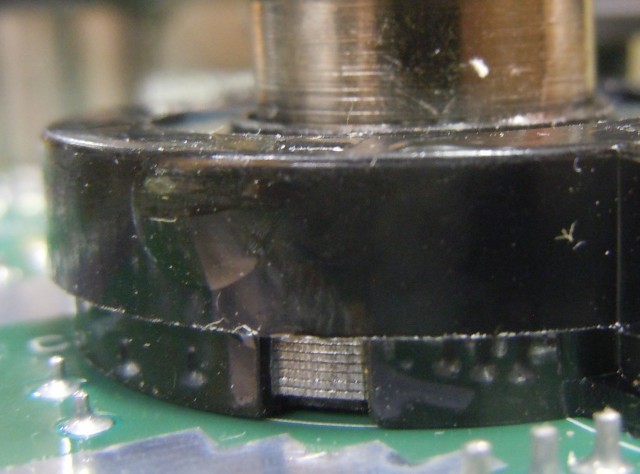

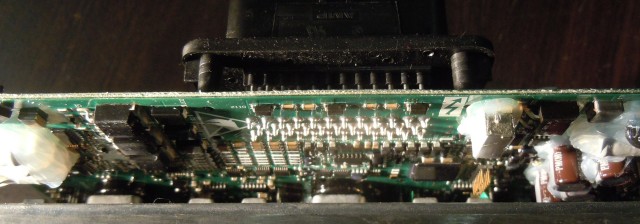

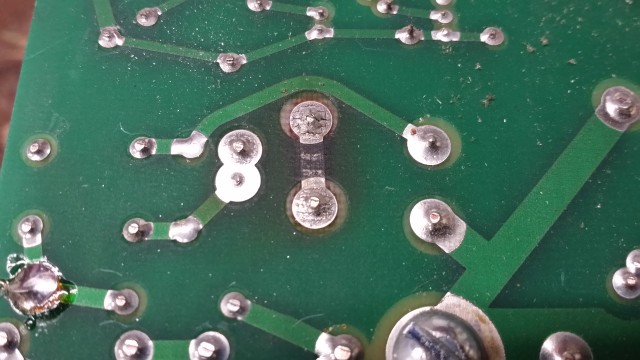

A couple of burnt up connections on some resistors

The EMI Filter has an absolutely dreadful layout, with long ground traces connecting to the Y caps.

And all the goodies left over at the end!

Want more high current ballast goodness? Check out the video teardown of the 7kW version of this ballast. Completely different architecture!